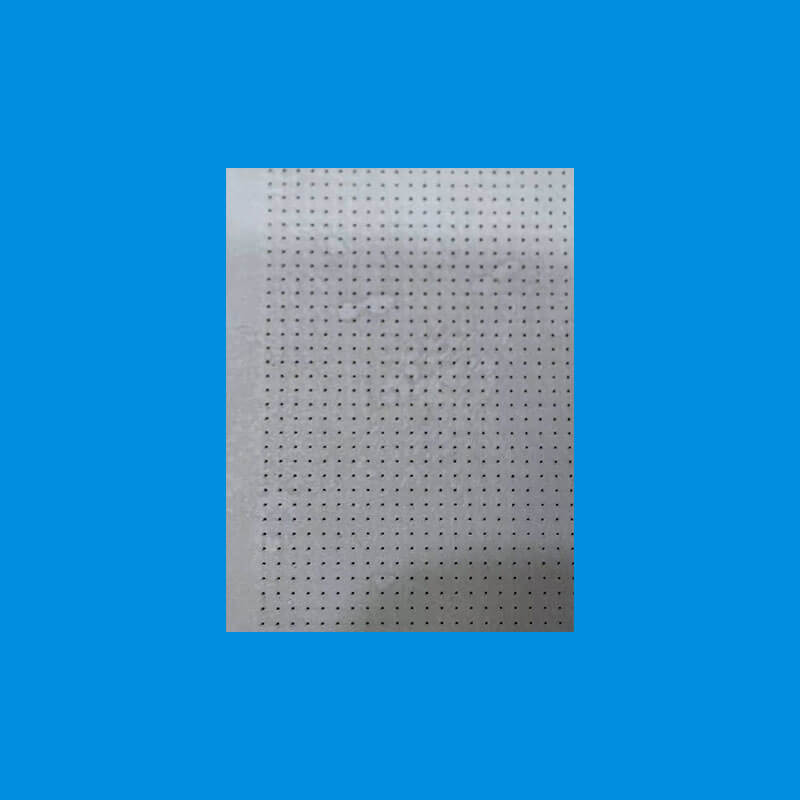

Ceramic material: aluminum nitride (AlN)

- Processing accuracy: +0.005mm

- Product features: wear-resistant, high temperature resistant, high hardness, high strength, high toughness

- Available color:White or light grey

- Customized processing: Customized processing can be made according to drawings

- Minimum Order:1 PC

- Delivery Time:3-25 days(depends on the quantity)

- Customization:Per your request

- Supply Ability:100000PCS/M( according to product structure)

- Payment Term:T/T, L/C, D/P.

Relative density 3.26; Mohs hardness 9; thermal stability up to at least 1800°C, and up to 2200°C

Product Details

Aluminum nitride is an inorganic compound with the chemical formula AlN. Aluminum nitride, a covalent bond compound, is an atomic crystal, belongs to diamond-like nitride, hexagonal crystal system, wurtzite-type crystal structure, non-toxic, white or off-white. Aluminum nitride (AlN) is a synthetic mineral and does not exist naturally in nature. The crystal structure type of AlN is hexagonal wurtzite type, with the advantages of low density (3.26g/cm3), high strength, good heat resistance (decomposed at about 3060℃), high thermal conductivity, and corrosion resistance. The pure product is bluish white, usually gray or off-white. Relative density 3.26; Mohs hardness 9; thermal expansion coefficient 4.84×10-6 K-1 (25~600℃); thermal conductivity 30.1W/(m.K)(200℃); resistivity 2×iolln,-cm (25℃)

Aluminum nitride (AlN) can be stable up to 2200℃. The room temperature strength is high, and the strength decreases slowly with the increase of temperature. It has good thermal conductivity and small thermal expansion coefficient, and is a good heat shock resistant material. It has strong resistance to erosion by molten metal and is an ideal crucible material for melting and casting pure iron, aluminum or aluminum alloy. Aluminum nitride is also an electrical insulator with good dielectric properties, and is also promising for use as an electrical component. The aluminum nitride coating on the surface of gallium arsenide can protect it from ion injection during annealing. Aluminum nitride is also a catalyst for the conversion of hexagonal boron nitride to cubic boron nitride. It reacts slowly with water at room temperature. It can be synthesized from aluminum powder in an ammonia or nitrogen atmosphere at 800~1000℃, and the product is a white to gray-blue powder. Or it can be synthesized by reaction of Al2O3-C-N2 system at 1600~1750℃, and the product is gray-white powder. Or it can be obtained by gas phase reaction of aluminum chloride and ammonia. The coating can be synthesized by vapor deposition method of AlCl3-NH3 system. AlN+3H2O==catalyst===Al(OH)3↓+NH3↑

Aluminum nitride ceramic is a new type of high-tech ceramic. Aluminum nitride substrate has extremely high thermal conductivity, non-toxicity, corrosion resistance, high temperature resistance, good thermochemical stability, etc. It is an ideal packaging material, heat dissipation material, circuit element and interconnection line carrier for large-scale integrated circuits, semiconductor module circuits and high-power devices. It is also the best additive to improve the thermal conductivity and mechanical properties of polymer materials. Aluminum nitride ceramics can also be used as crucibles for melting non-ferrous metals and semiconductor materials gallium arsenide, protection tubes for thermocouples, high-temperature insulation parts, microwave dielectric materials, high-temperature resistant and corrosion-resistant structural ceramics and transparent aluminum nitride microwave ceramic products, used as raw materials for the production of high thermal conductivity ceramics and resin fillers, etc. Aluminum nitride is an electrical insulator with good dielectric properties. The aluminum nitride coating on the surface of gallium arsenide can protect it from ion injection during annealing.

Video Center

Application Scenario